Beneficial monitoring: not whether, but when?

Posted: 26 September 2007 | | No comments yet

Achieving high levels of rail system reliability in all the phases of the life cycle at an optimal cost requires sound information, robust risk based analysis, proper implementation of asset management activities and on-going critical review.

Achieving high levels of rail system reliability in all the phases of the life cycle at an optimal cost requires sound information, robust risk based analysis, proper implementation of asset management activities and on-going critical review.

Achieving high levels of rail system reliability in all the phases of the life cycle at an optimal cost requires sound information, robust risk based analysis, proper implementation of asset management activities and on-going critical review.

Major rail organisations are actively interested in moving towards an ‘intelligent railway’ – monitored more effectively, at increased frequency and with the resulting information providing key input to the improved management of the railway assets. Monitoring can lead to large cost savings and increased operational reliability of both trains and track. Monitoring for maintenance purposes has been standard practice in aviation since the 1970s, but is still less common in many parts of Europe’s rail network. While some systems have had remote monitoring to some degree (e.g. telecommunications systems), other railway assets have been less well served.

In the drive for the intelligent railway, the Gotcha system is making a major contribution.

Plain grey boxes with a light-blue lid have now been in position for several years at forty-four carefully planned locations throughout the Dutch railway network. They were placed there as part of Gotcha, a system for monitoring rolling stock that was developed by Lloyd’s Register Rail and Baas in cooperation with infrastructure provider ProRail and train maintenance company NedTrain.

The Gotcha system detects every wheel of every passing train by means of optical sensors. This measured data, derived from the track mounted sensors coupled to an advanced calculation program, provides valuable information about the train, providing many benefits to operators and infrastructure managers.

Measurements from Gotcha clearly show wheel quality. Each locomotive and each coach has an identification tag and therefore it is possible to determine precisely which wheels are worn, and to what degree. Gotcha measurement data will also show which wheels are still in good condition.

This knowledge represents a revolution in the maintenance of rolling stock. Previously only ‘snapshots’ could be obtained for periodic checks. Gotcha provides real time information which is available on a continuous basis. Wheel quality data is therefore always up-to-date which is not possible using periodic checks.

Rolling stock can be maintained according to its condition with this improved up-to-date information instead of periodically as was previously the norm. Trainsets can easily be scheduled into the workshop when necessary rather than when a certain time period has elapsed.

This vastly improves the operational reliability of the track. We only have to think of weather conditions in the Autumn which can contribute to delays when rain and leaves on the track cause slipperiness when combined with ‘square’ wheels. Frequent and ongoing monitoring with Gotcha permits early signs of wheel wear to be recognised in time and ‘square’ wheels can be rectified before they cause problems.

Well maintained wheels last longer. In many cases, wheels can last 25 to 40% longer resulting in increased cost savings. In addition, perfectly round wheels are essential for the preservation of bogies since wheels that are flattened to any degree give rise to rattling wheelsets and thus rapid wear, leading to considerably higher maintenance and replacement costs.

Gotcha allows operators to realise large savings. It is self evident that the more vehicles that are monitored by the Gotcha system, the greater the savings will be. This does not mean that a large number of measuring stations needs to be installed. By strategic positioning of Gotcha stations a limited number of measuring points can suffice.

For example, by clever positioning in the Dutch network, the forty-four stations set up see as many as 95% of the trains at least once every two days. In practice it has been found that investment in Gotcha stations can be fully recovered within one year. This is an investment with a sound business case.

Following its rollout in the Netherlands, the system is also in use or under trial with eight other administrations across Europe. These include a network trial in Sweden and operational stations in Poland and Switzerland. The Gotcha system has also been selected as the preferred system for providing data for Network Rail’s developing Intelligent Infrastructure architecture throughout the UK network.

Infrastructure managers can benefit from the use of Gotcha as well as operators because better maintenance of rolling stock translates directly into less wear to the infrastructure and thus into lower maintenance costs. This ultimately can lead to lower transport costs.

Gotcha also offers another interesting option for infrastructure managers; the ability to establish the weight of each coach that passes over the sensors so that the track usage by various train operators can be ascertained simply and quickly. This makes transparent invoicing on the basis of tonnage a simple reality.

Gotcha, like many technology systems continues to evolve and other areas of measurement are possible. Environmental aspects such as noise reduction, air pollution and vibrations are obvious examples. Bearing monitoring is also possible and can reduce the costs of maintenance further by identifying hot or worn bearings.

Thanks to Gotcha’s systematic measurement, collection and analysis of data over the course of several years, a large database has now been created. This database is continuously being expanded and refined, and it offers a great deal of information of relevance to operators and infrastructure managers, information such as relative performance of tyres. This information can be used strategically allowing analysis of one brand against another. Of course, this can then have a direct impact upon maintenance costs.

It is clear that great benefit can also be gained by efficient monitoring for the track. The only question is: which party will take the initiative? The operator or the infrastructure manager? Clearly there are benefits for both, and strong leadership, coupled with proper engagement about the ‘intelligent railway’ will be essential.

It is an unavoidable fact that within a few years, monitoring will be just as prevalent on the railways as it is in aviation.

The question is not whether monitoring is coming, but when?

Gotcha reference cases

There are a number of Gotcha reference cases across Europe and they are presented here, split into first and second generation implementations.

The Gotcha first generation stations were installed in the Netherlands and installations of Gotcha second generation stations are throughout Europe.

Gotcha 1st generation

In 2000, Lloyd’s Register Rail and Baas Research started to work together on the development of the first generation Gotcha system. The development was done in close cooperation with the infrastructure manager, ProRail, and the rolling stock maintainer, NedTrain. Currently a total of 42 Gotcha first generation stations are installed along the track. The system has been functioning soundly for five years. The intention is to upgrade all first generation stations to second generation in due course.

The data produced by the stations is used by both ProRail and NedTrain and could in the future possibly be used by the train operating company Nederlandse Spoorwegen for passenger counting.

ProRail, project Quo Vadis (The Netherlands)

The Dutch rail infrastructure provider ProRail administers the 42 Gotcha first generation sites for collection of train weights on a total of 73 tracks. ProRail uses this information primarily for track-access charging based on total train weight. Intentions are to also charge customers based on the quality of their wheels in the future.

ProRail also uses the information to determine passing tonnage per day for every track. This information is used increasingly for maintenance and track degradation prediction.

NedTrain (The Netherlands)

More than 95% of the passenger rolling stock in the Netherlands is maintained in the workshops of NedTrain, a subsidiary of Nederlandse Spoorwegen (Dutch Railways).

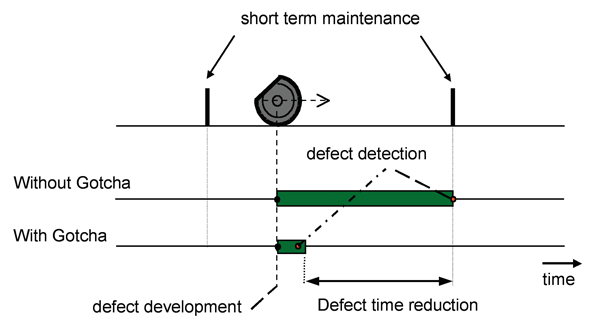

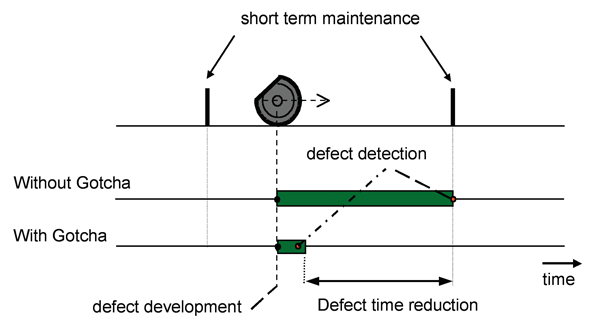

From the 42 Gotcha first generation stations installed along the track in the Netherlands, NedTrain draws on the data from 17 of them for wheel maintenance. Today the maintenance of wheels is mainly based on the information from the Gotcha stations. Figure 1 shows the theoretical influence of using the Gotcha system for maintenance control.

Based on the highest measured defect level a train is sent to the workshop. When a train comes to the workshop for regular short term maintenance, the information from Gotcha regarding defect levels can be viewed in order to decide which wheels need to be turned.

The introduction of Gotcha has had the following benefits:

- The fleet is effectively monitored on a daily basis (no excessive wheel defects for a longer period)

- Optimisation of wheel maintenance process

- 25-50% longer wheel tyre life

- 5-10% reduction of infrastructure maintenance costs

- 90% reduction of hot boxes

- Reduction of broken primary springs

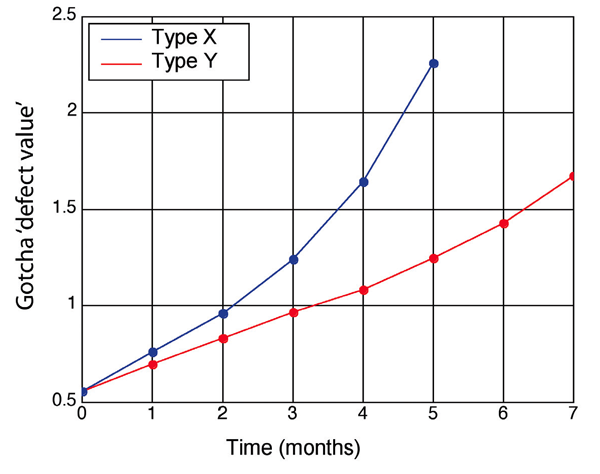

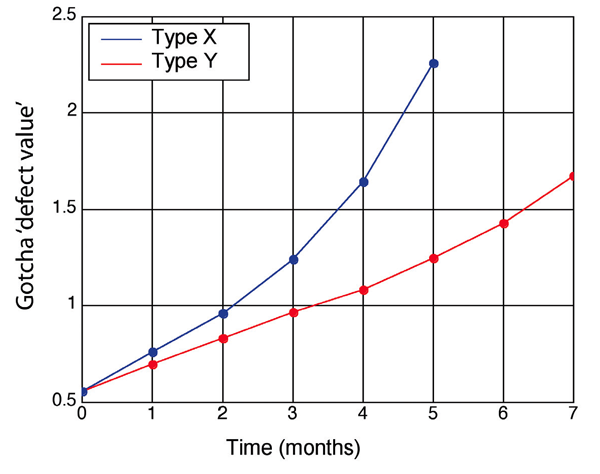

Lloyd’s Register Rail has performed several analyses based on Gotcha data to improve the maintenance cost. As an example, the degradation of two types of wheel tyre material have been compared (see Figure 2). Based on these results type Y is no longer used on this type of rolling stock.

Gotcha second generation

Since the second half of 2005, Lloyd’s Register Rail has placed several second generation Gotcha stations at different locations in Europe. To evaluate the functionality of these and to discuss requirements for future software updates and versions, an international Gotcha-user group will be set up. Some key installations are described here.

Banverket (Sweden)

In the second half of 2005 one Gotcha system was installed in Kiruna, Sweden. This station has been subjected to an extensive testing protocol by the Swedish infrastructure manager Banverket. The system has been successfully tested for:

- Stable operation (at extreme temperatures)

- Measuring vehicle weight and axle load

- Measuring (severe) wheel defects

- Measuring impacts with impact hammer and track loading vehicle

Banverket plans to use the system for both weighing in motion and wheel defect detection.

Polish Railways/TENS (Poland)

On the Poznan-Szczecin line two Gotcha systems have been operational since the beginning of 2006 and one system is installed at a test location. TENS have ordered an additional four systems in 2007.

Lloyd’s Register Rail’s partner, TENS, integrated the Gotcha system in their ASDEK system which is in use by Polish railways throughout the country.

The WIM-functionality of the Gotcha system has already been (temporarily) certified. The WDD-functionality is being tested at TENS’ test location.

Infraspeed (The Netherlands)

In cooperation with Belgium, the Dutch government has recently built a new high speed line between Amsterdam and Paris, called the HSL-Zuid. In 2006 Lloyd’s Register Rail placed two Gotcha stations along the track – both located on slab track.

The track maintenance is contracted by Infraspeed for the next 25 years and Gotcha will be used for asset protection and the rolling stock of HSA (High-Speed Alliance) will be maintained by NedTrain based on Gotcha data.

GVB (The Netherlands)

In the autumn of 2005, a pilot system was installed to monitor the trams of GVB Amsterdam. GVB experienced problems with polygonisation on their Combino trams. With the Gotcha system, Lloyd’s Register Rail has been able to successfully point out the wheels with polygonisation.

Rhätische Bahn (Switzerland)

The Swiss operator and infrastructure manager, Rhätische Bahn, plans to use Gotcha for condition-based maintenance of their rolling stock. In September 2006, the first system was installed in the Vereina tunnel (rock subgrade). This has offered Lloyd’s Register Rail the possibility to test the Gotcha system in a highly conditioned environment.

In Switzerland Lloyd’s Register Rail is cooperating with Bombardier Services. Bombardier uses the Gotcha data for their fleet management system.

Network Rail (United Kingdom)

In the United Kingdom, a Gotcha system is installed near Sevington, Kent. This system is part of a trial. The Gotcha system has been appointed as preferred bidder for the replacement of the WheelChex system currently employed by Network Rail.

Network Rail also purchased a mobile version of the Gotcha system which can be installed around the country.

Figure 1: Theoretical influence of Gotcha on maintenance control

Figure 2: Example of analysis with Gotcha data-wheel thread degredation

About the author

Ton Bontekoe is Product Manager – Gotcha, Lloyd’s Register Rail. He is a qualified mechanical engineer, specialising in Asset Management issues in the area of vehicle-track interaction. Mr. Bontekoe is responsible for the implementation of the Gotcha Asset Management platform at a wide range of rail administrations across Europe. With significant expertise in wheel – rail interfaces, Ton has many years experience in the economic and technical issues relating to performance and maintenance of wheel sets and their interaction with the track. Ton holds a Masters degree in Mechanical Engineering from the Delft University of Technology.

Issue

Related topics

Related organisations

Banverket, Infraspeed, Lloyd's Register, NedTrain, Network Rail, Polish National Railways, ProRail