A new type of railway mono-block sleeper

Posted: 1 August 2012 | | No comments yet

A railway sleeper is the structural element which transversally connects the two rails by means of fastening components, thus ensuring its gauge. Its additional function is to firmly secure the track to the ballast and to distribute the loads transferred from railway carriages to the ballast. One of the most important parameters in the characterisation of performances given by railway sleepers is represented by their lateral resistance to the sliding: the higher its value increases, the better the track stability becomes, thus reducing the frequency of maintenance interventions necessary to keep the superstructure efficient. This article focuses on the performance profile of an innovative railway sleeper, patented in Italy and called ‘EGA’ (High Performance mono-Block sleeper), under different efficiency conditions of the ballast. The research is carried out through a comparative assessment of traditional mono and bi-block sleepers, evaluating the resistance of the single sleeper thought as independent of the other constituents of the track.

The traditional ballasted railway superstructure normally involves the use of reinforced concrete mono or bi-block sleepers. More specifically, a reinforced concrete mono-block sleeper consists of a single concrete element, longitudinally pre-stressed and differently sized according to the railway networks in the various countries. In Italy, for instance, for lines running at a speed less than 200km/h, RFI S.p.A. generally employs a sleeper which is 2.30m-long, with a trapezoidal section and variable dimensions both in height and in width: maximum at the extremity (base width 30cm and height 19cm) and lesser at the centre (20cm and 15cm); the weight can range from 250 to 280kg1. A bi-block sleeper consists of two lightly reinforced concrete elements, held together by a steel tie rod whose function is to guarantee the correct track gauge and to keep the adequate spacing among the aggregates in the casting. Compared to mono-block sleepers, bi-block sleepers have greater resistance to lateral actions and lighter weight.

A railway sleeper is the structural element which transversally connects the two rails by means of fastening components, thus ensuring its gauge. Its additional function is to firmly secure the track to the ballast and to distribute the loads transferred from railway carriages to the ballast. One of the most important parameters in the characterisation of performances given by railway sleepers is represented by their lateral resistance to the sliding: the higher its value increases, the better the track stability becomes, thus reducing the frequency of maintenance interventions necessary to keep the superstructure efficient. This article focuses on the performance profile of an innovative railway sleeper, patented in Italy and called ‘EGA’ (High Performance mono-Block sleeper), under different efficiency conditions of the ballast. The research is carried out through a comparative assessment of traditional mono and bi-block sleepers, evaluating the resistance of the single sleeper thought as independent of the other constituents of the track. The traditional ballasted railway superstructure normally involves the use of reinforced concrete mono or bi-block sleepers. More specifically, a reinforced concrete mono-block sleeper consists of a single concrete element, longitudinally pre-stressed and differently sized according to the railway networks in the various countries. In Italy, for instance, for lines running at a speed less than 200km/h, RFI S.p.A. generally employs a sleeper which is 2.30m-long, with a trapezoidal section and variable dimensions both in height and in width: maximum at the extremity (base width 30cm and height 19cm) and lesser at the centre (20cm and 15cm); the weight can range from 250 to 280kg1. A bi-block sleeper consists of two lightly reinforced concrete elements, held together by a steel tie rod whose function is to guarantee the correct track gauge and to keep the adequate spacing among the aggregates in the casting. Compared to mono-block sleepers, bi-block sleepers have greater resistance to lateral actions and lighter weight.

A railway sleeper is the structural element which transversally connects the two rails by means of fastening components, thus ensuring its gauge. Its additional function is to firmly secure the track to the ballast and to distribute the loads transferred from railway carriages to the ballast. One of the most important parameters in the characterisation of performances given by railway sleepers is represented by their lateral resistance to the sliding: the higher its value increases, the better the track stability becomes, thus reducing the frequency of maintenance interventions necessary to keep the superstructure efficient. This article focuses on the performance profile of an innovative railway sleeper, patented in Italy and called ‘EGA’ (High Performance mono-Block sleeper), under different efficiency conditions of the ballast. The research is carried out through a comparative assessment of traditional mono and bi-block sleepers, evaluating the resistance of the single sleeper thought as independent of the other constituents of the track.

The traditional ballasted railway superstructure normally involves the use of reinforced concrete mono or bi-block sleepers. More specifically, a reinforced concrete mono-block sleeper consists of a single concrete element, longitudinally pre-stressed and differently sized according to the railway networks in the various countries. In Italy, for instance, for lines running at a speed less than 200km/h, RFI S.p.A. generally employs a sleeper which is 2.30m-long, with a trapezoidal section and variable dimensions both in height and in width: maximum at the extremity (base width 30cm and height 19cm) and lesser at the centre (20cm and 15cm); the weight can range from 250 to 280kg1. A bi-block sleeper consists of two lightly reinforced concrete elements, held together by a steel tie rod whose function is to guarantee the correct track gauge and to keep the adequate spacing among the aggregates in the casting. Compared to mono-block sleepers, bi-block sleepers have greater resistance to lateral actions and lighter weight.

On-field experiences, which were carried out in Italy from 2002 to 2005 on traditional lines and employed the diagnostic trains ‘Archimedes’ and ‘Taletes’, demonstrated that 92.6% of the track alignment faults and 82.6% of super – elevation faults occur in line sections with a nonvoid curvature (circular curves, clothoids and cubic parabolas)2. This can be due to the high lateral stresses in the track as trains pass by owing to the centrifugal force, which in the long run causes sleepers to be weakly clamped to the ballast with consequent variations in the original geometry of the track. In order to face these problems – whose solution can be reached only through frequent ordinary and/or extraordinary maintenance activities with high financial costs and deterioration in service levels for users (due to the necessity, for instance, to reduce the speed on faulty lines or to interrupt lines for maintenance work) – a new railway sleeper was designed, planned and patented, called ‘EGA’ (High Performance mono-Block sleeper)3. It is a reinforced concrete mono-block sleeper equipped with two lateral stoppers with a ‘clamping action’.

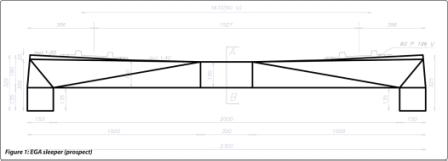

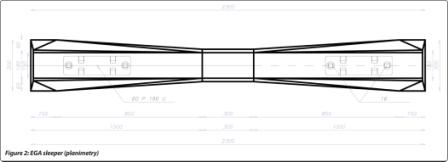

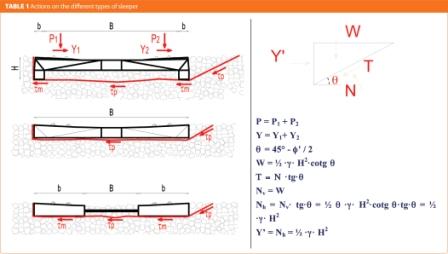

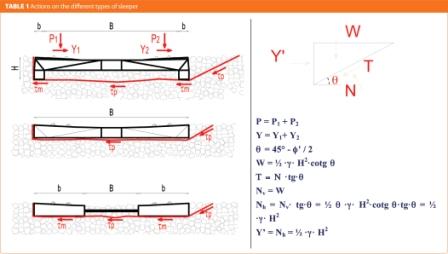

The sleeper, whose dimensions are illustrated in Figure 1 and Figure 2, provides the lateral actions with high resistance values under conditions of well-compacted and degraded ballast, as emerged by the analyses performed and better described later.

The lateral sliding resistance of sleepers

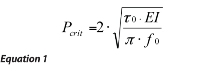

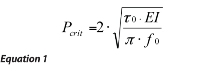

Railway sleepers should be tightly clamped into the ballast body so as to provide the sliding with high resistance values both lengthwise and crosswise. In particular, the specific lateral sliding resistance τ0 influences the critical load value Pcrit, the latter being the theoretical minimum axial load value which gives rise to the track ‘twist’. Assuming a track initially deformed by a sinusoid with an amplitude fo and a wavelength L, a track ‘frame’ characterised by a deflectional stiffness which is evaluated on the horizontal plane equal to EI, is able to stand an axial load Pcrit as shown in Equation 14.

Equation 1 shows the proportionality between the critical load Pcrit and the specific lateral sliding resistance τ0; therefore, a track marked by high values of τ0 is able to successfully stand thermal as well as lateral and longitudinal actions generated from railway carriages. The specific lateral resistance values, in case of an unladen track, are equal to τ0 = 11 kN in mono-block sleepers and τ0 = 14 kN in bi-block sleepers.

The evaluation of the lateral resistance of a railway sleeper can be carried out through two different criteria: the former, empirical, involves in situ tests with an unladen track; the latter, theoretical, involves the assessment of the resistance of the single element-girder thought as independent of the other elements forming the track frame through specific mathematical models. In order to adopt the latter approach it is required1:

- To set the stress friction angle of the ballast which, under condition of aggregates obtained from crushed stony rock with solid elements in low porosity and with sharp corners, can be assumed as equal to φ’ = 45°

- To set the specific weight of the ballast which, under ordinary conditions, can be evaluated as 15 kN/m3.

The comparative evaluation of the performances provided by traditional sleepers and by an EGA sleeper is made by taking the following two limit conditions into consideration:

- Condition A: Ballast in good condition (φ’ = 45°). In this case the friction angle between ballast and sleeper assumes such values which can be estimated through the relation φ’w = 2/3 φ’

- Condition B: Degraded ballast (φ’ = 35°). In this case, precautionarily the value of the friction angle can be set as φ’w = 1/3 φ’.

Performance of an EGA sleeper and comparison with traditional sleepers

In order to establish the behaviour of the new sleeper, it is hypothesized that a lithostatic stress distribution is determined in the ballast. Denoting respectively with P and Y the vertical and the horizontal actions transmitted from the train to the sleeper under study, with P1, Y1 and P2, Y2 the vertical and lateral actions to which each rail is subject, the equilibrium conditions illustrated in Table 1 (opposite) need to be verified under incipient motion, where θ is the inclination with regard to the horizontal plane of the incipient breaking zone, W is the ballast load in the breaking wedge, N and T the actions operating on the breaking surface.

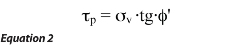

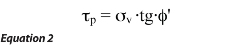

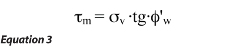

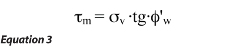

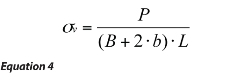

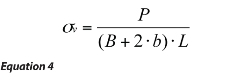

Denoting moreover with τm and τp the tangential stresses which appear at the level of the structure-ballast interface and in the ballastballast interface respectively (see Table 1 opposite), with σv the vertical stress and with L the width of the sleeper, the relations shown in Equations 2, 3 and 4 can be used.

Under the conditions of incipient motion, the total sliding resistance of the sleeper can be obtained from the sum of the elementary resistances offered by each component of the same sleeper and developing under each part of the structure denoted with letters ‘b’ and/or ‘B’ (see Table 1).

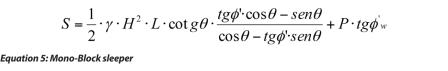

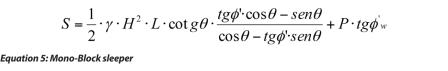

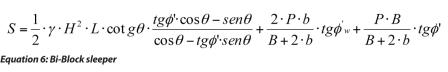

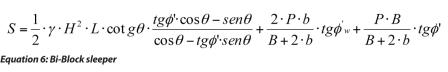

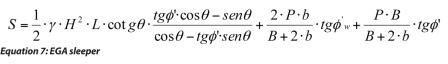

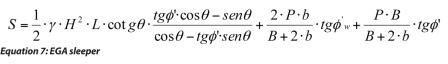

The equilibrium conditions5 are obtained by the expressions shown in Equations 5, 6 and 7 which give the lateral sliding resistance of sleepers whenever there are variations in their geometrical parameters, the mechanical properties of the railway ballast and the weight force (P) transmitted to each sleeper.

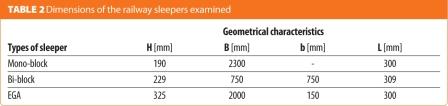

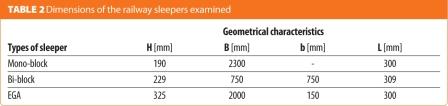

The conventional dimensions of the sleepers examined are shown in Table 2.

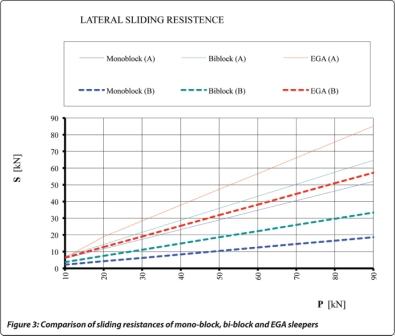

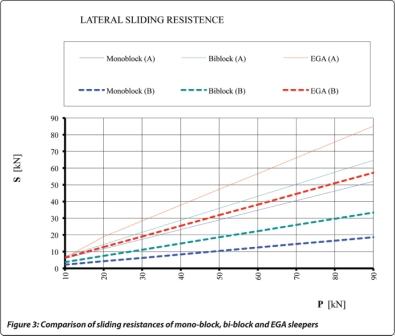

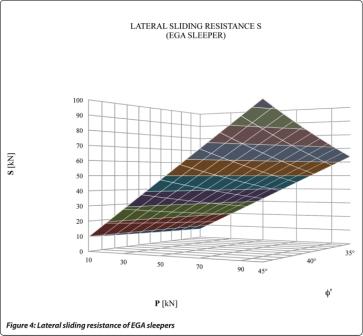

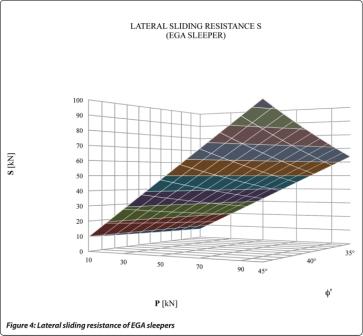

Figures 3 and 4 show the variation in the sliding resistance (S) with regard to the sleepers under study in different ballast conditions (Conditions A and B). Figure 4 especially illustrates the law of variation of S when there are changes in the internal friction angle φ’ and the weight (P) transmitted from the railway carriage to each sleeper, inferred from the Equation 7.

By applying Equations 5, 6 and 7, it can be analytically verified that, in case of ballast in good condition (Condition A), a biblock sleeper provides an average resistance increase of approximately 23% compared to a mono-block sleeper. On the other hand, an EGA sleeper provides an average resistance increase by 32% and 63% in comparison with bi-block and mono-block sleepers respectively. On the contrary, if the ballast is degraded or old (Condition B), the performances of an EGA sleeper appear to be even more remarkable although there is a decrease in the sliding resistance in all the sleepers under study as a consequence of a decrease in the friction angles φ’ and φ’w. As a matter of fact, in this condition its resistance is on average greater by 71% than a bi-block sleeper and by 202% (about twice) than a mono-block sleeper (see Figure 3).

Conclusions

This article examines the performances of railway sleepers by comparing three different types of structure: mono-block sleeper, biblock sleeper and a recently devised and patented sleeper called ‘EGA’. The analyses carried out show how the lateral sliding resistance (S), a parameter influencing track stability, is closely linked to the mechanical ballast characteristics, to the sleeper geometry and to the acting vertical load (P). In all the sleepers under study, lateral resistance has been observed to decrease whenever the internal friction angle of the ballast was reduced, mainly after aging processes of the railway superstructure.

The EGA sleeper guarantees the average resistance increase by 32% with regard to a biblock sleeper and by 63% with regard to a mono-block sleeper in a ballast in good condition (φ’ = 45°). Moreover, in case of degraded ballast (φ’ = 35°), the performances of EGA sleepers appear to be even more remarkable: in fact, its resistance is on average greater by about 71% than a bi-block sleeper and by 202% than a mono-block sleeper.

With reference to its potential use, it is worth observing that, given its specific characteristics, an EGA sleeper can be well employed in especially stressed railway line sections, like the planimetric curves with a moderate radius (where track geometry alterations frequently occur) on ordinary railway lines or, inde – pendently of the planimetric curvature of the route, on the new high speed lines.

References

1. G. Bono, C. Focacci, S. Lanni, “Railway Track”, CIFI, 1997.

2. D. Di Vincenzo, M. Guerrieri, “Gestione e diagnostica della sovrastruttura ferroviaria. Un caso studio: la linea Palermo – Messina”, Argomenti, ISSN 1973-4220,-RFI n.7 (2005). Available: http://www.trenitalia.com/cmsfile/ allegati/rfi/ARGMENTI_7.pdf.

3. M. Guerrieri, “E.G.A. sleeper”, Patented Invention n. 0000262017 – 20/09/2004, Italian Ministry of Economic Development.

4. C. Esveld, “Modern Railway Track – second edition”, MRT Production, 2001

5. M. Guerrieri, Prestazioni delle traverse ferroviarie: confronto tra dispositivi tradizionali ed innovativi, Argomenti, ISSN 1973-4220, RFI n.10 (2006), pagg.143-152. Available: http://site.rfi.it/file_sito/ArgomentiNumero10.pdf

About the author

Marco Guerrieri graduated in 2001 cum laude in Civil Transportation Engineering. He received a PhD in Road Infrastructure Engineering from the Faculty of Engineering, University of Palermo (Italy), in 2006. He was Postdoctoral Researcher at the Department of Road Infrastructure Engineering from 2006 to 2009. Designed as Expert of the ICAR04 disciplinary sector (Road, Railway and Airport) at the University of Palermo from 2006 to 2009 and since May 2011 at the University of Enna ‘Kore’. From 2006 to 2011 he was a Professor in several university masters courses and, in the academic year 2010/2011, Professor of Transport and Mobility Infrastructures (Faculty of Architecture, University of Palermo). Since August 2011, he has been Postdoctoral Researcher at CRB (Faculty of Engineering), Perugia University. Marco is member of the Italian Society of Transport Infrastructures (SIIV), the Italian Railway Engineers College (CIFI) and the Italian Association of Traffic and Transport Engineering (AIIT). He is author of over 35 papers, patent of inventions and technical notes published on national and international congress and journals.